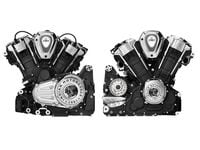

On October 29, Indian will release details on the new fixed-fairing Indian Challenger, its next-generation platform. Today, October 22, the company reveals that bike’s all-new PowerPlus liquid-cooled V-twin engine, whose styling is derived from the Scout powerplant. It is a 60-degree vee of 108.0mm by 96.5mm bore and stroke, with four valves per cylinder and hydraulic lash adjustment, actuated by chain-driven single overhead cams (SOHC). It makes a claimed 122 hp at 5,500 rpm, with peak torque of 128 pound-feet given at 3,800 rpm. Its unit construction architecture includes a gear primary drive to an integral six-speed transmission.

A week ago I flew to Minnesota to see this new engine, but in preparation I spoke by phone with Indian Director of Marketing Reid Wilson about the decision-making behind the project.

How did Indian decide the touring market was ready for a fully modern engine? In the recent past, progress has taken the form of modern technology add-ons applied here and there to make traditional designs keep up with interstate traffic. Who would take the step of designing a fully modern engine embodying traditional American feel?

I pointed to Harley-Davidson’s late-1970s decision not to build its liquid-cooled V-4 Nova, and to its 2017 discontinuance of the liquid-cooled V-Rod.

“The market has definitely evolved since then,” Wilson said. “And we make sure to evolve with it. A major element is the value riders now put on performance—the market for it is growing.”

I agreed. Touring engines have always grown with America’s highways and the expectations of riders. Sixty-ones became 74s, 74s became 80s, and today’s engines are more than 100ci. Highway speeds are high, making on-ramp and passing acceleration essential. This is a continuing trend.

I thought also about Indian’s past role as the innovator in American motorcycling. The original PowerPlus engine of 1916 was a great step forward, and I recalled Indian’s 1930s Chief Engineer C.B. Franklin’s innovative OHV engine development, which included four-valve cylinder heads.

Wilson made these points:

- American "feel" is all important.

- Riders want power and handling that give increased confidence.

- Riders and passengers want increased comfort—in particular, protection from wind and heat, plus freedom from intrusive vibration.

“These points are based upon real rider needs expressed by owners on all brands.”

When I arrived at the Wyoming-Minnesota engineering center, I was taken to the “Powertrain War Room” where a number of engineers introduced themselves. I was privileged to be receiving information at a high level.

Jay McKoskey, senior staff engineer, combustion, began by revealing the theme of this engine’s design: the shape of its torque curve. Traditionally, the touring curve has had a classic “lean-to” shape—with high torque at low revs, sloping downward as two valves per cylinder plus short valve timing ran out of breath as the engine revved up. That bottom-biased torque was essential to start and accelerate big motorcycles.Today, riders are finding “running out of breath” less acceptable because so much riding takes place on freeways where higher speeds emphasize midrange acceleration as well. For this, a “rainbow-shaped” torque curve can do better than just keep up with traffic: It gives strong reserve torque for confident passing.

Horsepower is easy to get—just extend valve timing to keep the valves open longer. But this weakens bottom-end—unacceptable in a touring engine. So to get the extra airflow to keep the engine from becoming short of breath as it revs up, you give up the smaller flow area of two valves per cylinder and adopt four. In an air-cooled engine, this creates a problem. The metal between each cylinder’s pair of exhaust valves, called the exhaust bridge, is heated from both sides. If it’s not cooled aggressively, its repeated expansion and contraction causes it to crack and/or to distort the valve seats, causing them to leak. This is why traditional air-cooled engines need help from local liquid-cooling (by oil or engine coolant).

McKoskey went on to describe what he was clearly proud of in Indian’s new engine: its intake ports. In a sportbike engine, the goal of using four valves is peak power, so its intake ports are dimensioned and aimed to deliver that. But to make strong midrange requires something different—to use more of the incoming flow’s energy to turn the fuel-air charge into an in-cylinder “flywheel” that keeps spinning as the piston comes up on compression. As the piston nears top dead center, that flow energy breaks up into turbulence that give fast, efficient combustion in the midrange, just what the touring rider needs in fast-moving modern traffic.

Justin Short, engineering supervisor, motorcycle powertrain development, at this point noted that, "We make sure that the hardware we build actually confirms their assumptions."How do you measure such fuel-air charge motion in an engine cylinder? Not so long ago it was done with an actual wind gage, an anemometer, in the cylinder. Today the method is Particle Image Velocimetry—basically adding dust to the intake flow and analyzing its motion to give a clear picture of in-cylinder dynamics. Metrics of charge rotation are derived from that. Call or write AVL Tippelmann for details.Another problem of traditional air-cooled engines, much as many love them, is that of excessive piston temperature. Anything that heats the fuel-air charge entering an engine pushes engine combustion closer to detonation, or "knock." Because knock can be destructive, it must be avoided. A primary source of heat flowing into the fresh charge is the piston crown. It is cooled mainly by the piston's close contact with the cylinder wall. If that cylinder wall is cooled by air alone, its temperature can be quite high, resulting in hotter pistons. Because of that, air-cooled engines must be given lower compression ratios. Because compression ratio is a prime determinant of engine torque, that reduces torque.

Best, therefore, to begin with an all-liquid-cooled engine whose cylinder walls are always kept close to coolant temperature rather than yo-yoing with the weather. That in turn pulls down piston temperature, allowing the use of a higher torque-boosting compression ratio. In this engine compression its 11:1. Another point is that piston durability depends strongly on temperature.

Like all modern engines, this one carries a knock-detection system which retards the spark if detonation is detected, then gradually returns timing to normal. A single vibration pickup generates a signal that is filtered to eliminate all but the range of frequencies that deto produces, and is “windowed” (that is sampled only in the range of crank angle at which detonation occurs) to produce a clear knock/no-knock signal. I’ve seen many pistons wrecked by detonation and wish I’d had such a system back then.

After an early lunch we visited the dyno rooms and I saw a complete engine, set up for testing. Big V-twins look huge out of the chassis! And next came the feast—a room in which a disassembled engine had been laid out on a number of tables. This engine had completed 135 hours of running that alternated between peak torque and peak power. Here were the engine’s Nikasil-lined cylinders, bristling with thermocouples for temperature measurement. I next went to the pistons, which have a wider skirt on the thrust side, narrower on the non-thrust side. Both bear a panel of black solid-film break-in lubricant. There was not a mark on them. This is the message of modern design: When oil is always present and its temperature and quality are within limits, wear is near zero.

An important contrast between pistons designed for liquid-cooled as opposed to air-cooled engines is that their piston rings can be located closer to the piston crown, minimizing the volume of fresh charge that is forced into the ring crevice space, emerging during the following power and exhaust strokes to become unburned hydrocarbons (UHC) in the exhaust. The cooler the piston runs, the higher you can locate its rings without the danger of their sticking from heat-polymerized lubricant. On these pistons the rings were down just 4.5mm (my estimate).

Because these pistons will not experience anything like the peak accelerations found in high-revving sportbikes they have a simpler and more organic shape. Because this engine is liquid-cooled, they have modern short skirts and boxlike “slipper piston” design. The underside of each one’s crown is further cooled by a crankcase-mounted oil jet. Thinking of those hard 135 test hours I turned one over to find only a reassuring light brown discoloration.

The connecting rods are steel and fracture-split, with plain bearing big ends. Rod caps are retained by bolts. The small ends are tapered to widen the support of the wrist pin in its bosses. Rods run side by side on a single crankpin, just as rods do in classic American V-8 auto engines. The forged one-piece crankshaft is a mighty work: Do 30 curls with this crankshaft every other morning and your biceps will become magnificent. A balance shaft reduces vibration.

Some traditionalists may question the bore and stroke of 108.0mm by 96.5mm because the bore is larger than the stroke. Stop that nonsense! Chevy’s great 427 V-8 was 108.0 by 95.5mm and no one will tell you it lacked torque. Indian built one of the first versions of this engine at 104mm by 104mm (107ci), found its vibration at the 6,500-rpm redline excessive, and therefore reduced the shaking by adopting the shorter 96.5mm stroke it now has. Eight of Indian’s cylinders, built as a V-8, would produce 11 percent more torque than that 427, and at a lower rpm.

This engine’s combustion chambers are designed to maximize the fuel-air charge that has burned before the expanding flame front first touches cool metal. To this end, the valve included angle (how far the intake and exhaust valve stems are splayed apart) is made larger than fashionable in sportbike circles (that is, the combustion chamber is deepest under the central spark plug) and the piston crown is slightly dished. Combustion transforms the chemical energy of the fuel into heat, heat makes pressure, and for peak efficiency that pressure has to go straight to work pushing pistons rather than just making them hotter.

To put the ignition sparks “out in the wind” where the flame kernel can spread rapidly, the single central spark plugs have projected iridium tips. To keep them at a long-life temperature, they have extra-long reach that allows them to be closely surrounded by circulating coolant.

The valves themselves are not the largest that could fit into the 108mm diameter of the chamber. Why? This was done to put the regime of optimum port flow where the engine spends most of its time—in the midrange.

Each overhead cam has two lobes, driving forked intake and exhaust roller rocker arms. Opening each valve and made as part of the rocker arm is an HLA—engineer-speak for hydraulic lash adjuster, but “hydraulic lifter” to the rest of us. Actual driving contact with each valve stem tip is by an element that is flat facing the end of the valve stem, but part spherical where it fits into the HLA unit. Lift force is transmitted through a long-wearing broad area rather than a point or line contact. Look at one of the 56 rocker arms on Pratt & Whitney’s 28-cylinder R-4360 aircraft piston engines of the 1950s, and you’ll find the same feature.

“These riders do a ton of miles,” I was told by more than one of my informants. “It is not on their agenda to pause for an expensive dealer valve clearance adjustment at the halfway point of a trans-continent tour.”Chains drive the cams from the crank, guided and hydraulically tensioned via two-piece molded-plastic shoes. The shoes I saw had been equipped with thermocouples to measure their temperature during development testing. Oil is pumped to the chains and a cup where they pass under the crank sprockets. Why two pieces? One is the structural part, stiffened by filling with glass fibers, and the surfaces that guide and tension the chains are pure polymer.

The vertically split crankcases show the effects of a weight-saving program that pared 35 pounds from the prototype; their shape is cored wherever possible in very detailed ways. Crankshaft main bearings are rugged plain sleeves as in automotive practice, and oil is supplied to the crankpin from those bearings via drillings.

A crankcase reed valve allows piston motion to pump case pressure negative (reducing parasitic losses), and effluent from this valve is routed up a “chimney” behind the rear cylinder to a volume at the rear of the main chassis beam. This system condenses oil vapor and returns it to the oil system.

The six-speed gearbox (“with true Over Drive”) resides behind the crank. The first gear pair have straight-cut teeth but the upper five ratios are helical for noise reduction and load sharing by multiple tooth pairs.

Shifting is by dog rings rather than by sliding the gears themselves. It is interesting to note that the two-speed gearboxes on the Indians that finished 1-2-3 in the 1911 Isle of Man TT were shifted by dog ring.

Patrick Rohlman, design manager, powertrain, noted that because there is not enough oil flung from the crank to lubricate the transmission, six oil squirts are provided, aimed at the dog rings and the three shift forks that move them.

Primary drive from crank to the multi-plate clutch is by hefty gears and there is an assist feature to lighten rider clutch lever pull. Softening the torque pulsing from the engine are six robust helical springs in the clutch basket. On the other end of the crank is a spline-driven (no taper to weld itself in place!) outer rotor 660W (max) alternator and the one-way starter drive. For those accustomed to starters on four-cylinder engines (smaller “bites” of air to compress during starting), this starter is substantial. And it is assisted by a centrifugally deactivated decompressor that slightly lifts the exhaust valves.

Powerful engines generate a lot of heat. At lower speeds a fan directs hot air from the coolant radiator downward rather than toward the rear. When stopped in traffic a cylinder deactivation system cuts fuel and spark to the rear cylinder, allowing its exhaust pipe to cool rather than bake the right legs of rider and passenger.

Eric Fox, senior staff engineer, powertrain calibration, indicated a flow chart on the wall that was at least 10 feet long. It describes what occurs between the rider’s throttle grip and the resulting throttle-plate angle inside the very compact Bosch ECU, which measures and controls through a pair of “million-pin connectors.” It offers three ride modes with individual throttle mapping and traction control intervention levels. Calibration is the process of getting the desired output from all the necessary inputs. When I visited this company during development of its first “Victory” V-twin engines years ago, much of calibration was carried out by a long-suffering engineer with a laptop, jolting along in a sidecar attached to the test machine.

Half of the work of calibration focuses on “hitting the numbers” in tail pipe emissions. We were shown examples of engine 3-D maps presenting rpm, throttle angle, and torque. As there are as many as 18 mutually interacting maps involved. “If you don’t get it right, you get unanticipated results.”

Another image compared a jagged-looking 3-D engine map (it looked like a fracture surface!) with one that resembled rolling hills. Fox said, “We’d never run something as pointy as that, and I might even take down the top of that hill on the smooth map.”

The goal is seamless engine response. Think of this as being analogous to the mutual adaptation of horse and rider. Fox emphasized the necessity of data acquisition; there are 10 to 12 bikes in the calibration program, doing 15,000 test miles a year.

“Humans are still required to evaluate all this!” he said.

And so it should be—because it is humans who will ride the result!

To sum up, the development of Indian’s new engine employs the best tools and technologies of modern engineering to specifically serve the evolving needs of today’s touring riders, while preserving the American “feel” that is admired by so many around the world.

Sign up here to receive our newsletters. Get the latest in motorcycle reviews, tests, and industry news, subscribe here for our YouTube channel.

/cloudfront-us-east-1.images.arcpublishing.com/octane/AAN4TI76M5H5JMUVEIGASWXBDU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/P3RXD2UCPFF37CMB7CHPVKXORY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VZEG2EJI2RDFZNHLRZMU56MD3Q.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/GVJQO5FFOFBWNGODOBRB4FBAW4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/BIVAK2SFIBDJJM25E7I5VU2FJE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CH5VX52UG5CFHOVH5A6UYEFWWA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZVGJNGZRU5C33N7KN23BBFKSC4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CZ5OM3E43ZEXJHY7LCYXCHLIKI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/DF5T4K5KPZFJXFCTGPYR77PKJM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/RMCT2KVQBJHBZMRTSLOVPMOILU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K45KB2XHQVA65DX7VN4ZSMT2BI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/FNHXQQ56BRD7TO4YIJ453PNG2M.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/OIKJC4JA3ZH7BMKUGWYKBIY5FA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/MT2SAEWY6FDXFBYSLDE3AEFDTM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/66UPKPYVURBPRCP5HXSN56MEMM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/EOREGDSRKFDCRJC6K3EDVHBGCE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/42RF63Q3LVCMBP3DGTWXFYSMOA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/XNVY3EVWZFCEVPUGJGAN633LXE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/2PLTVHXY7FDSPFHKU5CFOC43ZY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/B6M3WTRLFZGNXBEATNXPVGBBD4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/4CMH3FI73BEM5D6MFYX42FLDSQ.jpg)