While there’s been a headlong rush to develop automated manual transmissions for motorcycles over the last year or two Honda’s E-Clutch stands alone as a low-cost compromise that retains a standard manual shift while eliminating the need to use the clutch lever.

Honda has been an advocate of letting the technology shoulder the load when it comes to gearshifts for years, having persisted with the clever-but-complex DCT (dual clutch transmission) in bikes from the Gold Wing to the Africa Twin over the last decade and a half. But it’s more recently that others have awoken to the idea, seeing the increasingly strong take-up rates among Honda buyers for those DCT-equipped models and rushing to get their own autos into production. BMW, KTM, Kawasaki, and Yamaha have all launched automated manuals over the last couple of years, all opting to simply add electronic actuators to conventional manual boxes and their clutches rather than pursuing the seamless-shift, dual-clutch route that Honda took with DCT.

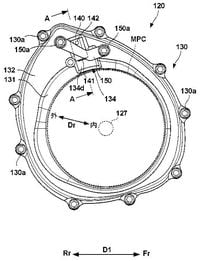

Honda’s response? The E-Clutch, launched on the 2024 CB650R and CBR650R, which cleverly automates clutch operation without the need to make major changes to the engine itself. A new clutch cover incorporates an actuator with dual electric motors acting via gears on the clutch release. Allied to a few additional sensors and a control unit, it automatically engages and disengages the clutch as required, while you still shift cogs with your left toe. Smarter still, it even retains the conventional clutch lever and cable operation, so you can ride the bikes in a completely conventional, manual-clutch mode or override the computer at any time. Compared to rival automated manuals and Honda’s own DCT, E-Clutch is incredibly cheap and easy to apply to virtually any bike. This year it’s been added to the Rebel 250 in the Japanese market and the Rebel 300 and CL300 in some other Asian areas, with more bikes sure to follow.

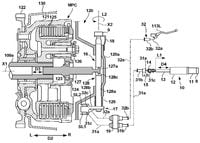

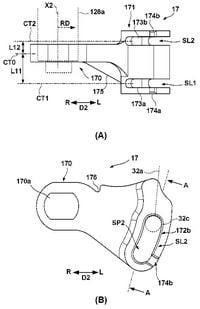

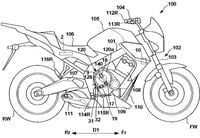

So what’s next? Honda is developing the idea to be even cheaper and more adaptable. A new patent from Honda illustrates a development on the E-Clutch idea that eliminates some components and allows the clutch actuator to be mounted virtually anywhere rather than on the clutch cover. While the patent itself focuses on the detail of a temperature sensor in the system, used to make sure the clutch isn’t getting overworked, it shows a version of the E-Clutch that dispenses with the existing actuator and the gear-drive system connecting it to the clutch release mechanism, replacing it with a linear actuator and a second clutch cable exactly like the one connected to the standard clutch lever.

The two cables—one from the standard lever, the other from the linear electric actuator—are both connected to the clutch release arm, which has two parallel slots, one for each of the cables. The design means that either the manual lever or the electronic actuator can disengage the clutch, and the actuator can be mounted anywhere on the bike, as it only needs a flexible cable to connect it to the clutch release arm.

As on the existing E-Clutch bikes, the system requires a couple of sensors alongside the actuator and the control unit—most importantly a load sensor in the shift linkage to detect when you’re swapping cogs—and ties into existing sensors for throttle position, gear position, and wheel speed to get the information required to work properly. The existing E-Clutch adds only around $200 to the cost of the CB650 models in markets where they’re offered in both fully manual and E-Clutch forms (in the US, the E-Clutch is now standard on those bikes), and the version seen in the latest patent has fewer bespoke components so should be even more cost effective.

/cloudfront-us-east-1.images.arcpublishing.com/octane/YMWAIPIPSJAOXOU3QMJMGH37OM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/EJ6KZRGAYBCVXNL2PJXL37UVWQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/AAN4TI76M5H5JMUVEIGASWXBDU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/P3RXD2UCPFF37CMB7CHPVKXORY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VZEG2EJI2RDFZNHLRZMU56MD3Q.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/GVJQO5FFOFBWNGODOBRB4FBAW4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/BIVAK2SFIBDJJM25E7I5VU2FJE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CH5VX52UG5CFHOVH5A6UYEFWWA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZVGJNGZRU5C33N7KN23BBFKSC4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/CZ5OM3E43ZEXJHY7LCYXCHLIKI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/DF5T4K5KPZFJXFCTGPYR77PKJM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/RMCT2KVQBJHBZMRTSLOVPMOILU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K45KB2XHQVA65DX7VN4ZSMT2BI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/FNHXQQ56BRD7TO4YIJ453PNG2M.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/OIKJC4JA3ZH7BMKUGWYKBIY5FA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/MT2SAEWY6FDXFBYSLDE3AEFDTM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/66UPKPYVURBPRCP5HXSN56MEMM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/EOREGDSRKFDCRJC6K3EDVHBGCE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/42RF63Q3LVCMBP3DGTWXFYSMOA.jpg)